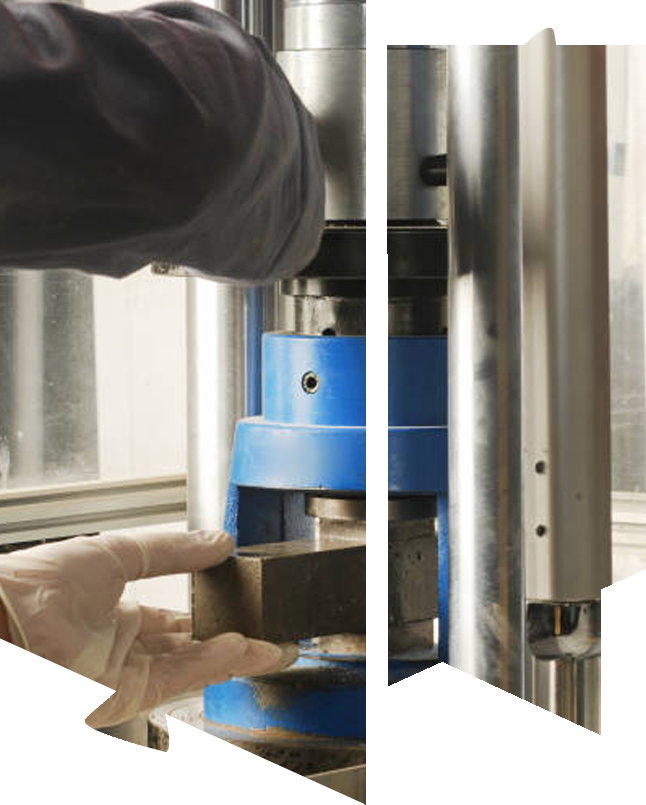

Concrete Test Equipment

Leading Manufacturer & Supplier of Concrete Testing Equipment in India

About our Company

Engineering Solutions Equipment

Founded in 2017, Engineering Solutions Equipment is a top manufacturer in India and a trusted supplier of high-quality soil testing equipment, cement testing equipment, concrete testing equipment, bitumen test equipment, steel testing equipment, and other essential civil laboratory instruments. Serving clients across Delhi NCR, Delhi, and the entire Indian market, our products are known for their accuracy, durability, and affordability. Whether you’re looking for top-rated soil testing machines, liquid limit apparatus, cement testing equipment, the Best civil lab equipment supplier in Delhi, or concrete testing equipment, we provide solutions that meet your industry’s needs and expectations as the best manufacturer in India.

products range

Our categories

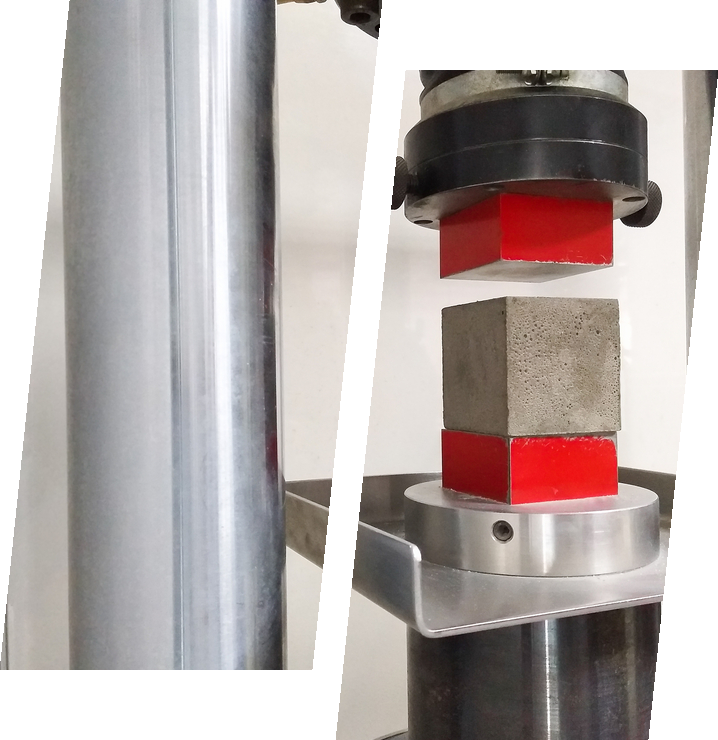

Featured Products

Our Products

Our Awards

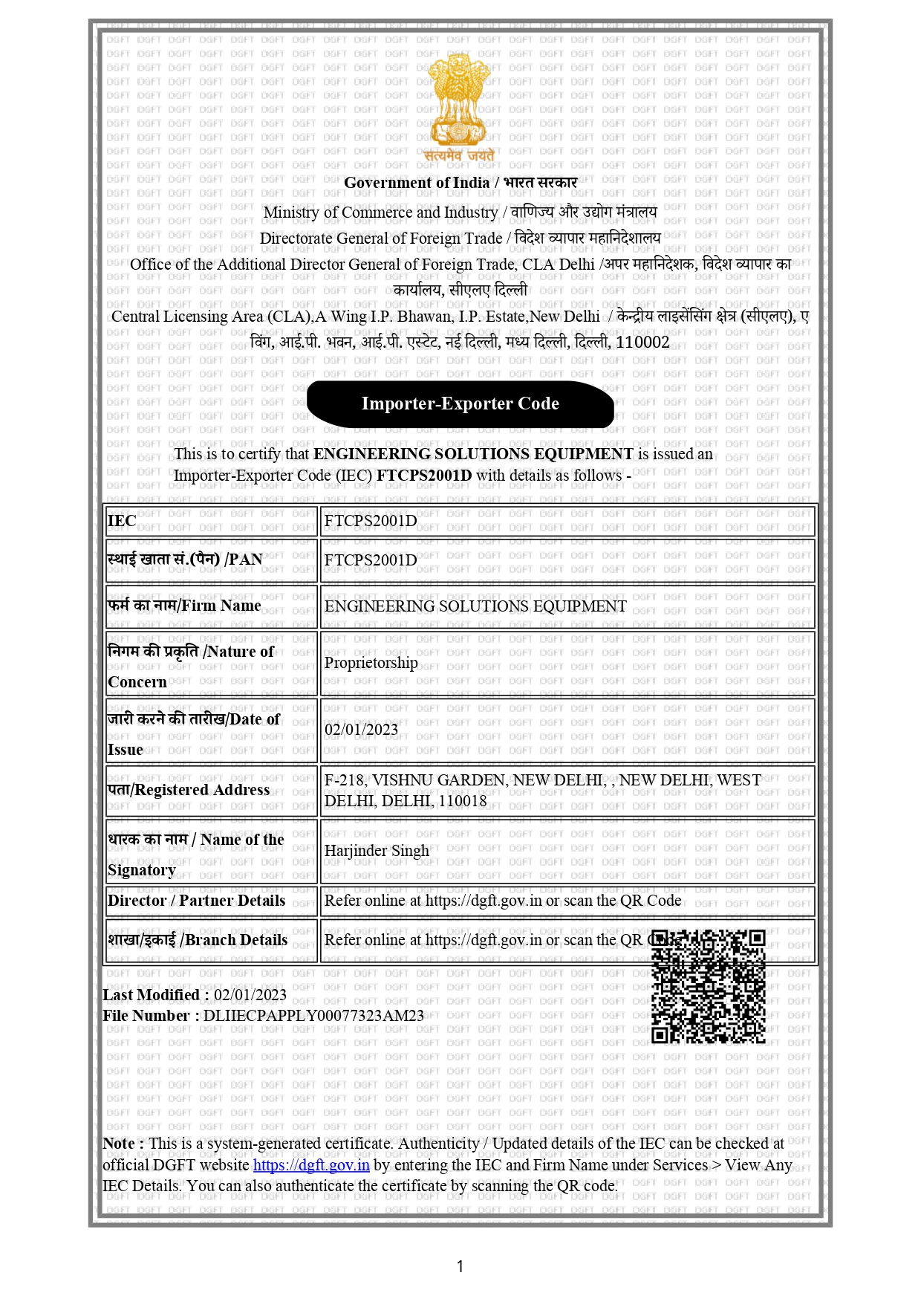

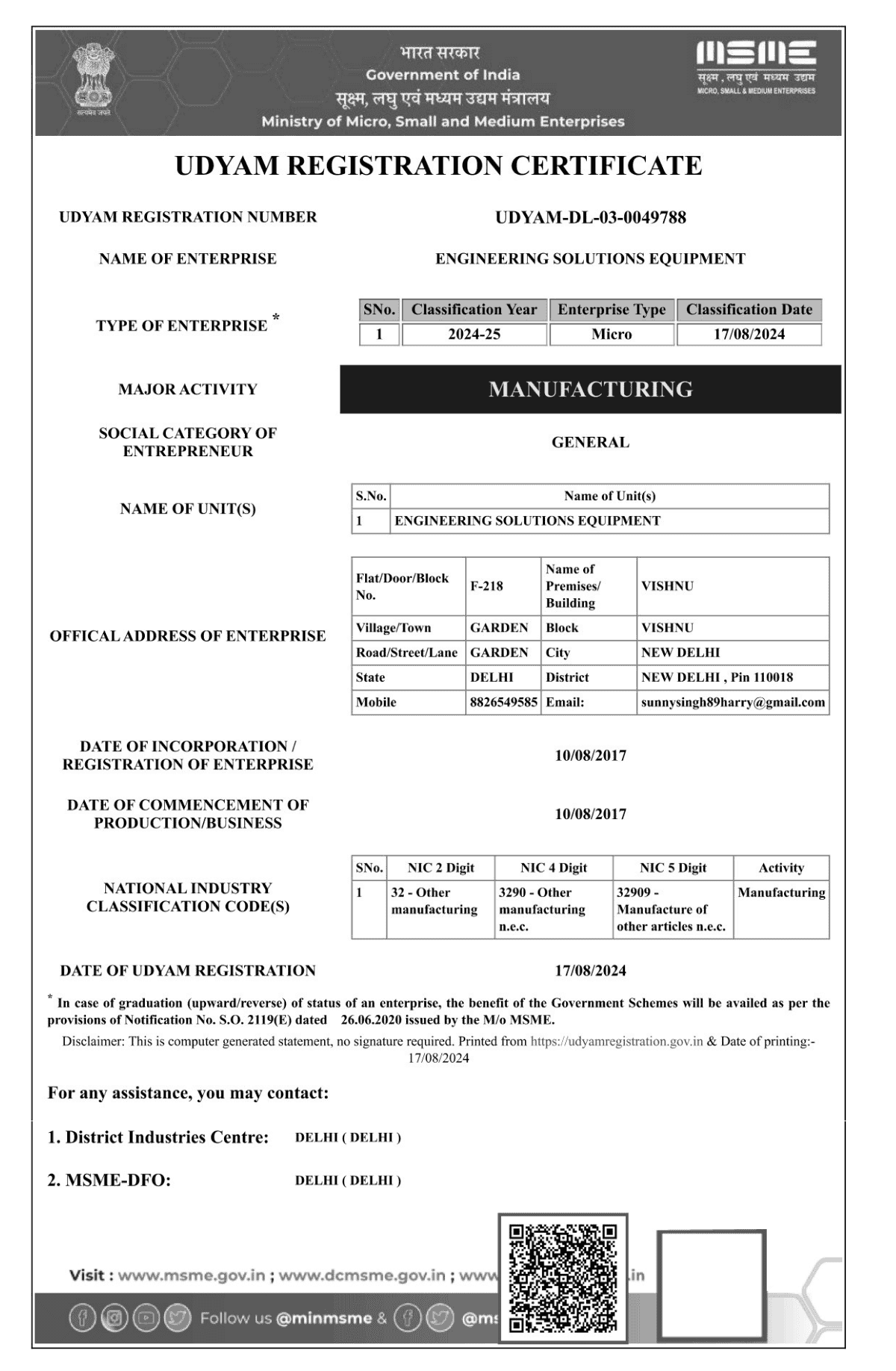

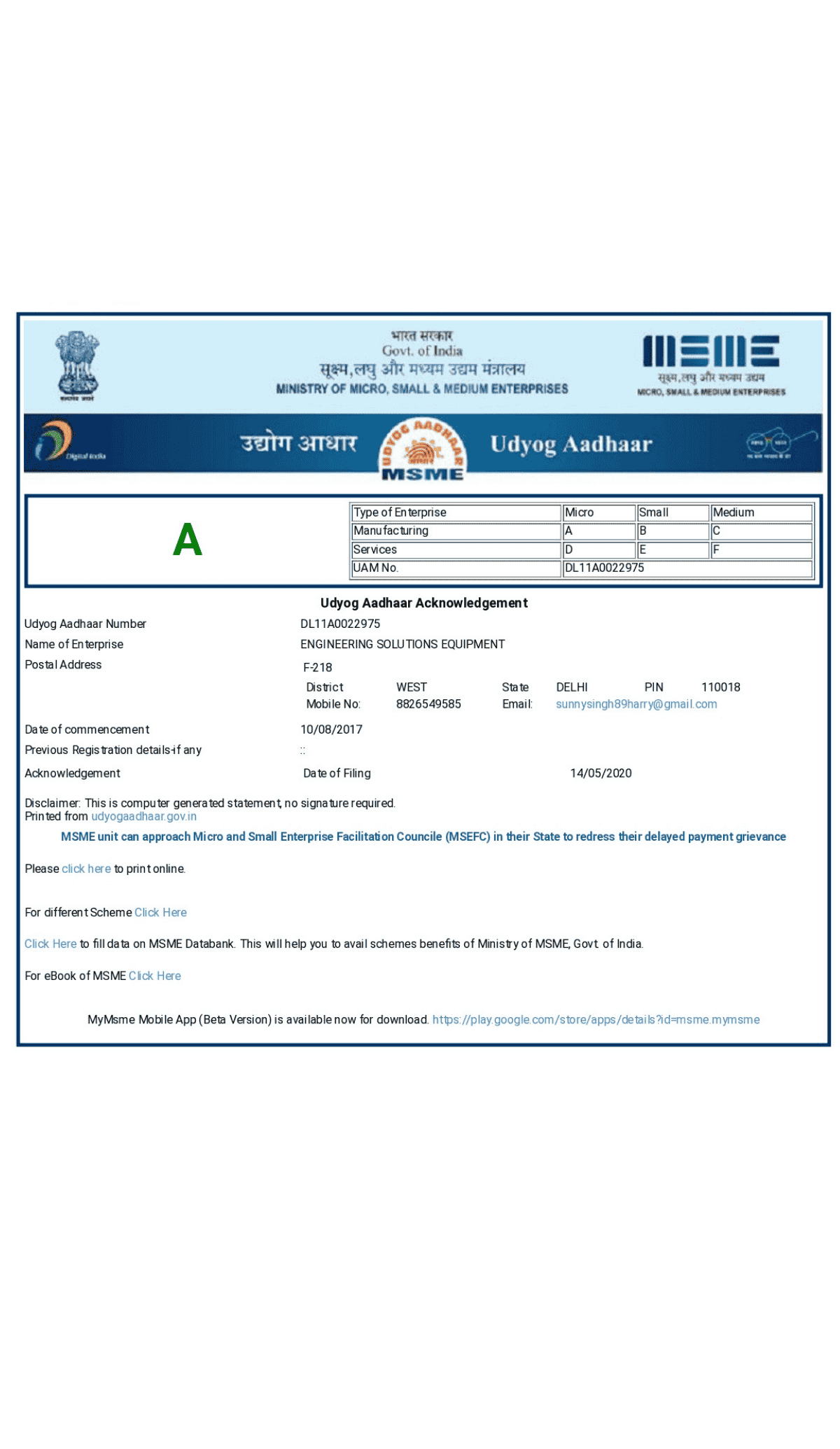

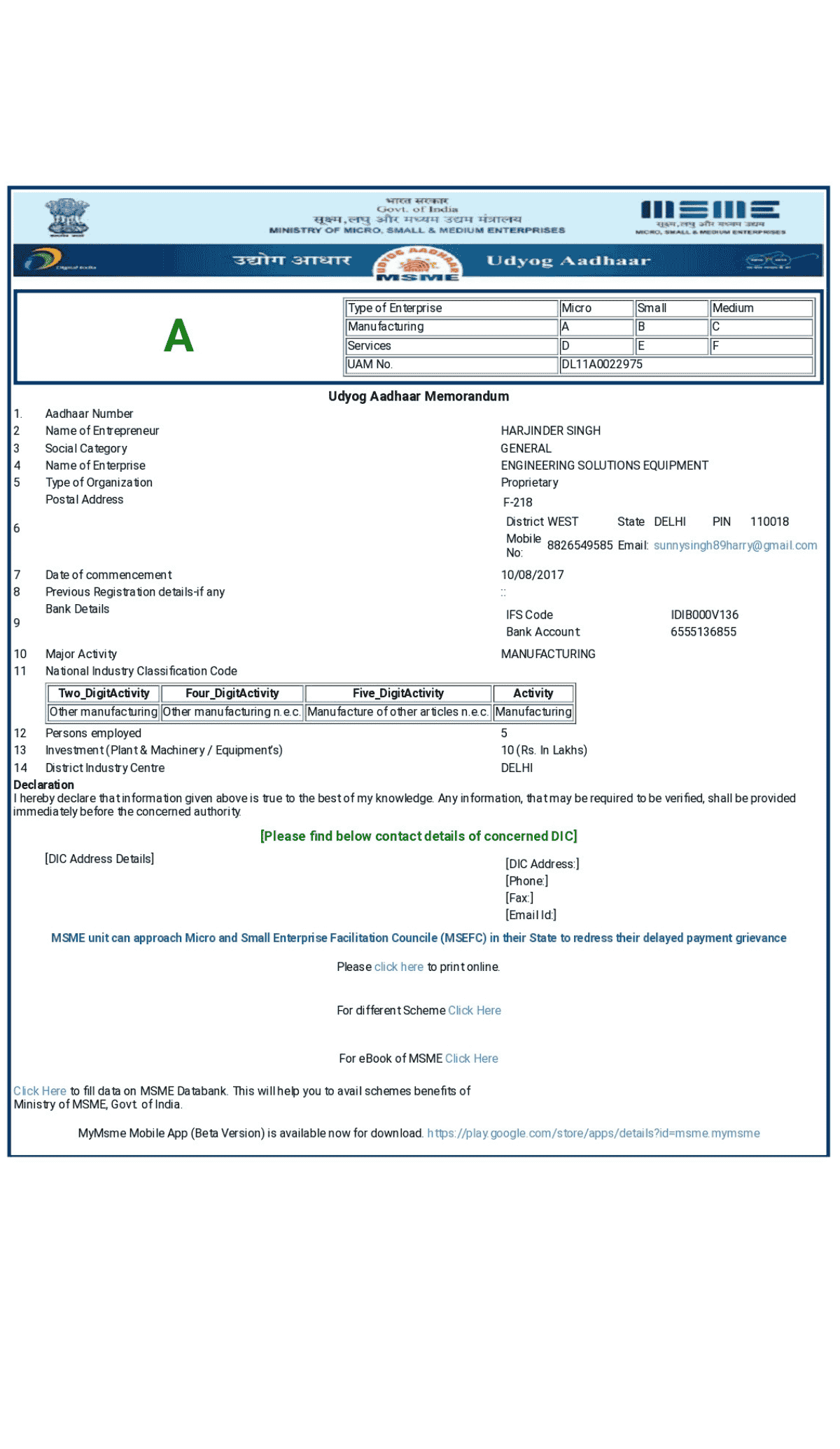

Certificate

WHY CHOOSE US

We Are Different Than Others

Experience

With over 21 years of experience, Engineering Solutions Equipment is a top manufacturer in India, known for reliable soil testing equipment, cement testing equipment, and concrete testing apparatus. We serve clients across Delhi NCR and India, offering unmatched expertise and high-quality solutions.

Superior Quality

We are committed to delivering high-quality testing equipment such as soil testing equipment, cement testing equipment, and concrete testing apparatus to our clients in Delhi NCR and across India. Every product undergoes rigorous quality control to ensure reliability, durability, and precision. Our focus on quality has made us the trusted choice for testing apparatus in Delhi NCR, Delhi, and nationwide.

Honest and dependable

Engineering Solutions Equipment is committed to delivering honest and reliable service to clients in Delhi NCR, Delhi, and across India. We build long-lasting relationships based on trust, transparency, and customer satisfaction, ensuring our clients receive dependable testing equipment and services.

Very Competive Rates

At Engineering Solutions Equipment, we offer competitive pricing for soil testing equipment and concrete testing machines in Delhi NCR, Delhi, and nationwide. Our pricing ensures that industries and laboratories across India can access high-quality products without exceeding their budget, providing exceptional value for businesses in Delhi NCR, Delhi, and beyond.

Certificates Company

Engineering Solutions Equipment .A well-established and esteemed manufacturer of civil laboratory equipment. With a solid 21-year legacy in the industry, Engineering Solutions Equipment has consistently set benchmarks for quality and innovation, and I am eager to contribute to its continued success.

Organization Setup

A civil engineer works intimately with a city’s landmarks and other ancient monuments that are part of the city’s heritage.

FAQ'S

Frequently Asked Questions

We manufacture a wide range of soil testing equipment, including liquid limit apparatus, sand testing machines, Atterberg limit apparatus, and more. These products are specifically designed to meet the requirements of civil engineers, construction companies, and testing laboratories in Delhi NCR, Delhi, and across India.

Yes, our concrete testing equipment is suitable for both small and large-scale construction projects in Delhi NCR, Delhi, and beyond. Whether you’re testing concrete strength or durability for a skyscraper in Delhi NCR or a residential project in Delhi, our equipment ensures accurate and reliable results.

Yes, we offer customized testing equipment solutions tailored to the unique needs of civil engineering firms in Delhi NCR. Whether it’s specialized soil testing machines, sand testing equipment, or other civil lab apparatus, we are committed to delivering equipment that matches your specifications in Delhi NCR and across India.

Placing an order for soil testing equipment is easy! Simply contact us via phone or email, and our team in Delhi NCR will guide you through the selection process, provide product details, and offer a customized quote. We cater to customers in Delhi, Noida, Gurgaon, and surrounding regions of Delhi NCR.

Yes, we provide delivery services for all our testing equipment to locations across Delhi NCR, including Delhi, Gurgaon, Noida, and other cities across India. We ensure timely and reliable delivery for all orders, whether for individual labs or large-scale construction projects.

Our sand testing equipment pricing varies based on model specifications, quantity, and customization. We offer competitive rates for sand testing machines in Delhi NCR and throughout India. Reach out to our sales team in Delhi NCR for a customized quote based on your needs.

Yes, we offer samples of our soil testing equipment for clients in Delhi NCR and across India. You can request a sample to evaluate the quality and functionality of our soil testing machines before placing a bulk order for your civil testing needs in Delhi, Delhi NCR, or any other location.

Yes, all our soil testing equipment and concrete testing apparatus are manufactured according to industry standards and are approved by the relevant regulatory bodies in Delhi NCR and throughout India. Our products are designed to meet the stringent requirements of civil engineers and testing labs in Delhi, Delhi NCR, and nationwide.

Yes, we provide comprehensive after-sales support, including installation and maintenance, for all our soil testing equipment in Delhi NCR. Our team is ready to assist you with installation, troubleshooting, and regular maintenance, ensuring your equipment continues to perform optimally throughout its lifespan.

Absolutely! We offer free customized quotes for all our concrete testing equipment. Simply contact us with your project details in Delhi NCR, and we will provide a quote tailored to your needs. Our team in Delhi NCR is available to discuss pricing and help you find the right equipment for your construction project.

Testimonial

What Our Clients Say

Best Compression Testing Machines manufacturers in India, Quick & excellent Services.

Anil Nandeshwar

Best Compression Testing Machines and Top quality civil lab equipments available here.

Hema Grover

Get in Touch with Engineering Solutions Equipment for Testing Equipment in Delhi NCR and India

Looking for reliable soil testing equipment suppliers or concrete testing equipment manufacturers in Delhi NCR, Delhi, or anywhere in India? Contact us today to inquire about our range of products, request a quote, or learn more about how we can help meet your civil testing needs with high-quality solutions.