Close

ESE-435 – Air Entertainment Meter

| Attribute | Details |

|---|---|

| Material | Stainless Steel |

| Capacity | Customized |

| Measurement Range | 0-100% |

| Accuracy | ±0.5% |

| Display | Digital |

| Power | Electric |

| Usage/Application | Industrial, Laboratory |

| Dimensions | Customized |

| Weight | Standard |

| Country of Origin | Made in India |

Product description

An Air Entertainment Meter is a device used in engineering and environmental testing to measure the amount of air required to entertain (or suspend) solid particles, typically in processes involving the movement or handling of powders or particulates, such as in material handling systems, pneumatic conveying, or dust collection systems. It measures the air flow or pressure needed to keep particulates suspended in a fluid (typically air), which is critical in industries like pharmaceuticals, mining, cement, and powder coating, among others.

In simpler terms, the meter helps determine the fluidization point of materials—how much air is needed to make a solid material behave like a fluid in a given system, which helps in optimizing the performance of pneumatic systems and ensuring efficient operation.

Key Features and Specifications:

- Measurement Parameters:

- The Air Entertainment Meter typically measures the flow rate or pressure of air required to lift or suspend particulate materials.

- It provides measurements in terms of CFM (Cubic Feet per Minute) or m³/h (Cubic Meters per Hour), depending on the scale of the system.

- Design:

- The device usually consists of a flow meter, a pressure gauge, and a flow regulator. The setup is designed to simulate the conditions under which the air needs to interact with the particulates, allowing accurate readings.

- It can be built to test single-phase air systems or multi-phase systems involving a combination of air and material flow.

- Material Compatibility:

- The Air Entertainment Meter is constructed to handle a wide range of materials, from fine powders to coarser grains. The design may include materials resistant to wear and corrosion, such as stainless steel or high-grade alloys, to handle abrasive particulates.

- Applications in Material Handling Systems:

- This meter is especially used in pneumatic conveying systems to assess and adjust the air flow necessary to transport powders or granules through pipelines.

- It is used to ensure that the material is sufficiently suspended, reducing clogging and improving the efficiency of the material transport process.

Related Products

-

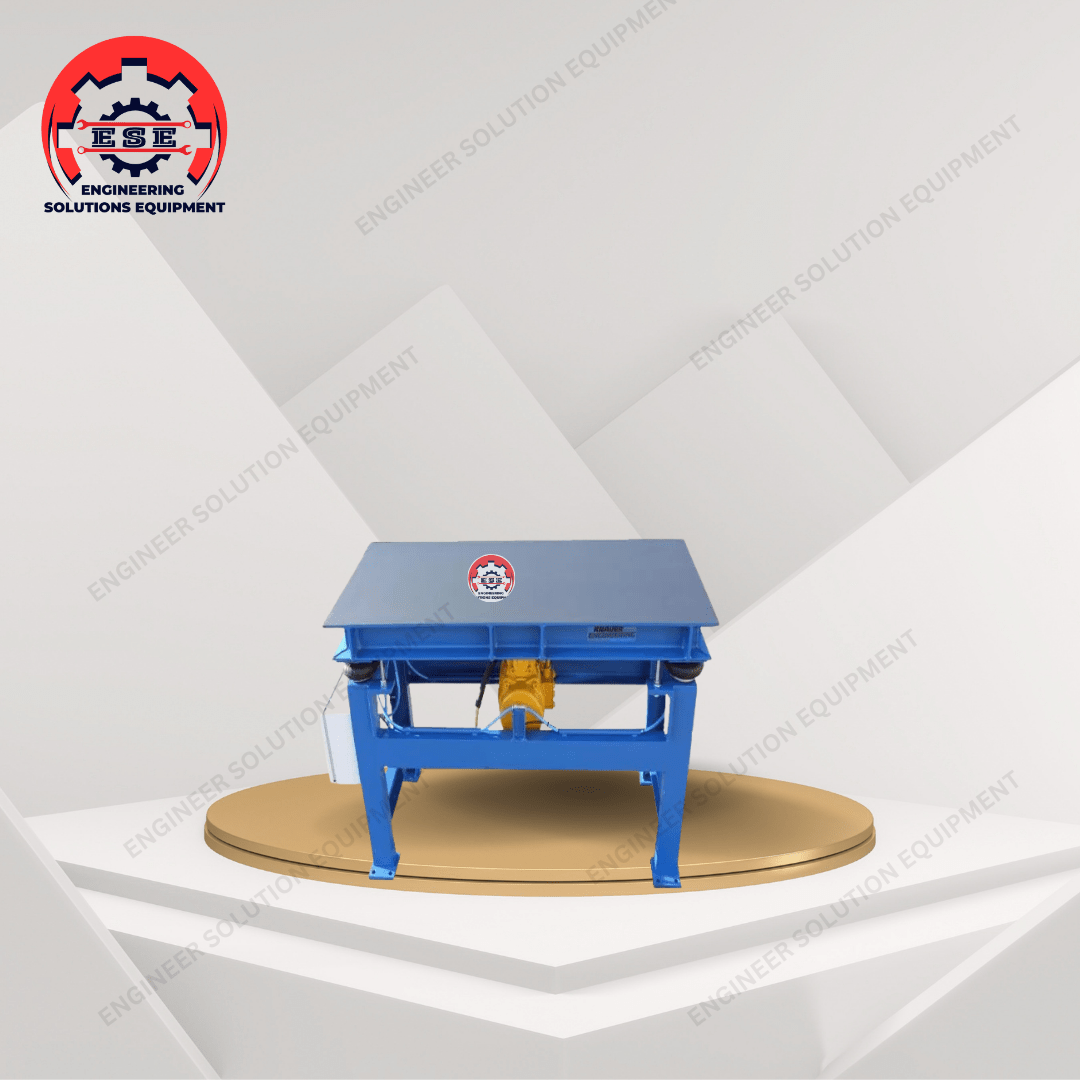

ESE-185- 1mtr x1 mtr Vibrating Table For Cube

Concrete Test Equipment -

ESE-712- 24X24 Vibrating Table.

Cement Testing Equipment -

ESE-406-Scoop

Steel Testing Equipment -

ESE-501-Slump Corn Test

Rock Testing Equipment -

ESE-540-Concrete Cutter

Rock Testing Equipment -

ESE-540-Core Drilling Machine

Rock Testing Equipment -

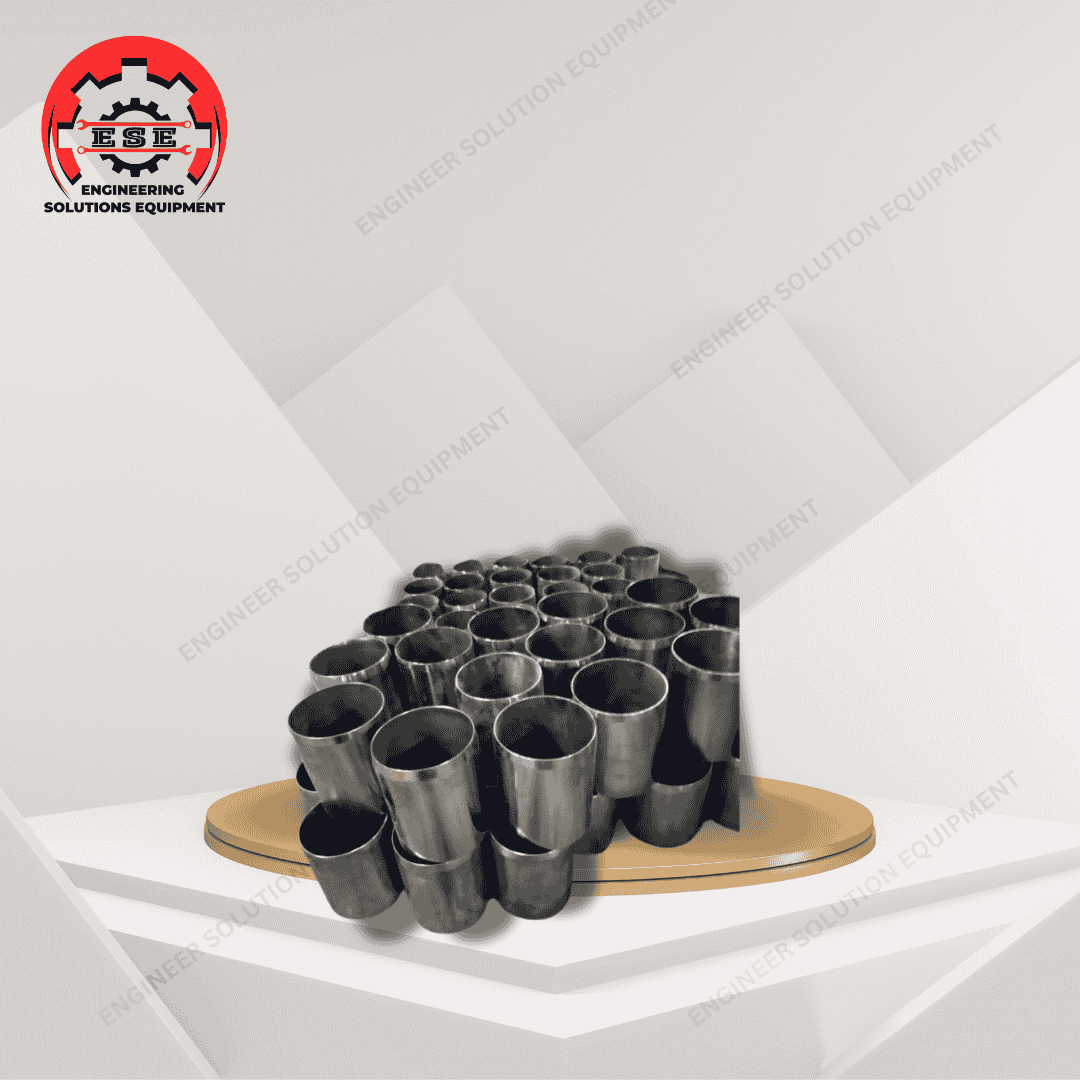

ESE-079-Core Cutter With Dolly

Soil Testing Equipment -

ESE-152 – Digital CTM Plate Model

Concrete Test Equipment