Close

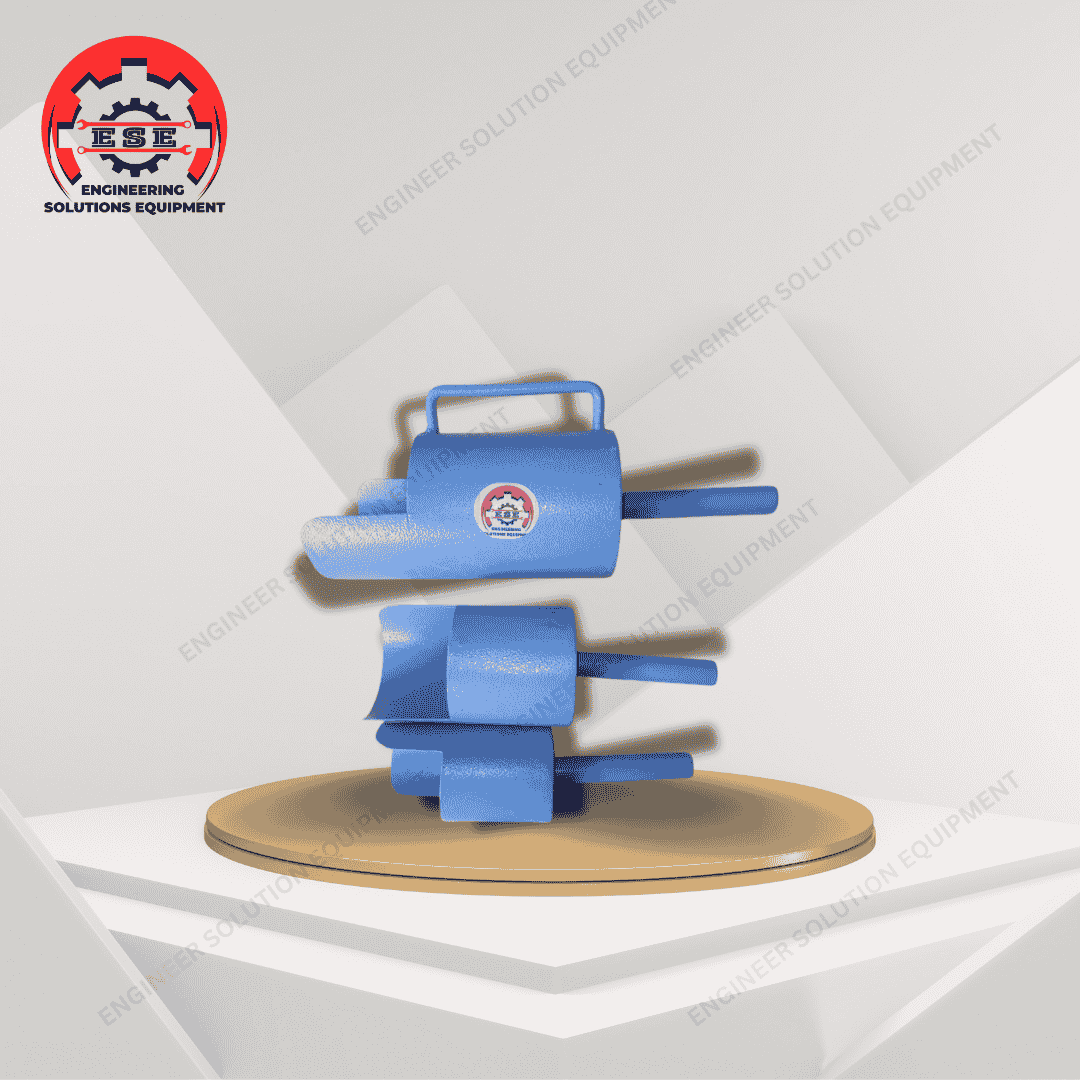

ESE-505-Rock Bolt Pullout Test

| Attribute | Details |

|---|---|

| Test Name | Rock Bolt Pullout Test |

| Test Method | Pullout Test (Force Measurement) |

| Test Type | Destructive Testing |

| Capacity | Up to 1000 kN (Depending on Model) |

| Load Measurement | Digital Load Cell or Analog Load Gauge |

| Accuracy | ±1% of Full Scale |

| Load Frame | Hydraulic or Mechanical Test Frame |

| Fixture | Specialized Clamps for Rock Bolts |

| Measurement Units | kN (Kilonewton) |

| Display Type | Digital Display for Load Measurement |

| Test Speed | Controlled (Typically Slow and Steady) |

| Frame Type | Vertical or Horizontal, Depending on Test Setup |

| Power Source | Electric (for Hydraulic Units), Manual (for Mechanical Units) |

| Hydraulic Pressure | Up to 700 bar (for hydraulic models) |

| Usage/Application | Mining, Tunneling, Underground Construction, Geotechnical Testing |

| Weight | Varies Based on Load Capacity and Frame Size |

| Size/Dimensions | Customized Based on Testing Requirements |

| Color | Metallic (Typically Silver or Blue) |

| Packaging | Wooden Case or Box for Safe Transportation |

| Country of Origin | Made in India |

Product description

The Rock Bolt Pullout Test is a critical laboratory testing procedure used to evaluate the performance and strength of rock bolts, which are commonly used in tunneling, mining, and civil engineering projects for stabilizing rock masses. This test measures the resistance of a rock bolt to axial pullout force, simulating the conditions it would experience in actual service. By determining the pullout strength of rock bolts, this test ensures that the bolts are capable of withstanding the stresses and loads they will encounter, contributing to the safety and stability of structures.

Key Features:

- Accurate Load Measurement: Measures the force required to pull out the rock bolt from the surrounding rock or grout, providing an indication of its anchorage strength.

- Simulates Field Conditions: Designed to replicate real-world stress conditions, ensuring that the test results are relevant for practical applications.

- Versatile Testing Capacity: Capable of testing different types and sizes of rock bolts, as well as various anchorage materials (e.g., grout, resin).

- Precise Control: Includes adjustable settings for controlling the load rate and test duration, ensuring flexibility for different testing requirements.

- High Load Capacity: Engineered to withstand high pullout forces, making it suitable for testing large-diameter bolts and high-strength anchorage systems.

- Robust Construction: Built with durable materials that ensure long-lasting performance even under heavy-duty testing conditions.

Related Products

-

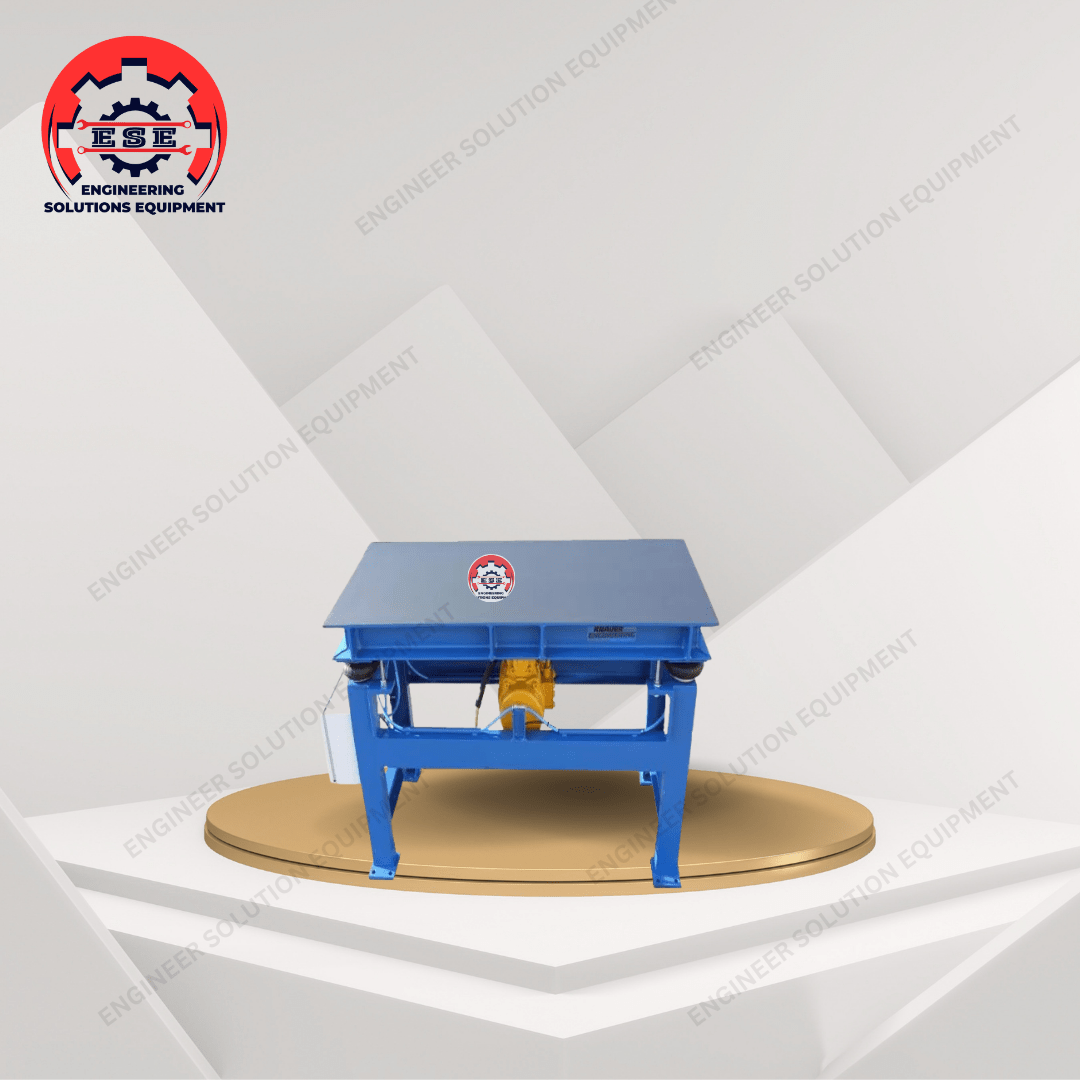

ESE-185- 1mtr x1 mtr Vibrating Table For Cube

Concrete Test Equipment -

ESE-712- 24X24 Vibrating Table.

Cement Testing Equipment -

ESE-406-Scoop

Steel Testing Equipment -

ESE-501-Slump Corn Test

Rock Testing Equipment -

ESE-540-Concrete Cutter

Rock Testing Equipment -

ESE-540-Core Drilling Machine

Rock Testing Equipment -

ESE-079-Core Cutter With Dolly

Soil Testing Equipment -

ESE-152 – Digital CTM Plate Model

Concrete Test Equipment