Close

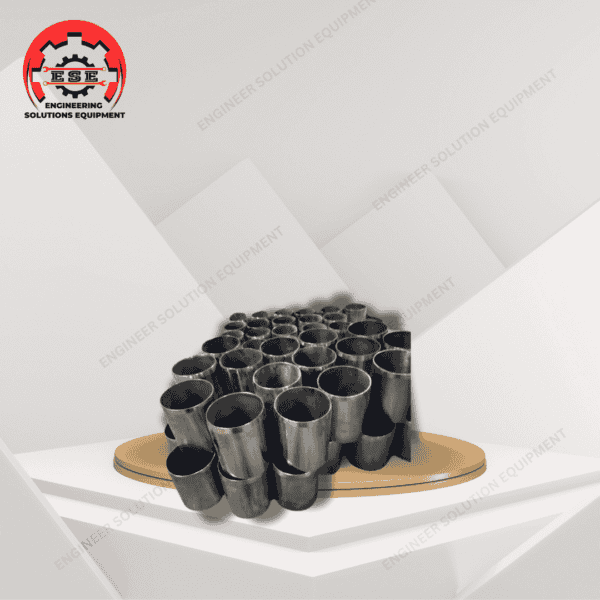

ESE-079-Core Cutter With Dolly

| Attribute | Details |

|---|---|

| Material | High-quality mild steel or stainless steel for durability and resistance to corrosion |

| Core Cutter Size | 100mm diameter x 130mm height (standard size) |

| Dolly Material | Aluminum or mild steel with a flat top for uniform distribution of force |

| Handle | Sturdy and detachable handle for easy operation |

| Hammer Weight | Typically 2.5 kg (to be used with the cutter and dolly) |

| Application | Used to determine in-situ density of compacted or undisturbed soils |

| Compliance | Conforms to IS 2720 standards |

| Weight | Approximately 3–5 kg for the entire set |

| Accessories | Includes rammer, dolly, and other necessary components |

| Finish | Powder-coated or polished for a smooth finish and rust resistance |

| Environment | Suitable for field and laboratory soil testing applications |

Product description

Product Overview of Core Cutter with Dolly

- The Core Cutter with Dolly is a precision-engineered tool supplied by a reputed Concrete Testing Equipment Manufacturer, widely used in soil testing laboratories.

- It is specifically designed to determine the in-situ density of compacted and undisturbed soils, a crucial parameter in geotechnical and construction projects.

- Manufactured using high-quality mild steel or stainless steel, this apparatus offers long-lasting durability and resistance to corrosion, guaranteed by a trusted Concrete Testing Equipment Manufacturer.

- The complete set includes a core cutter, dolly, rammer, and handle, ensuring ease of use in both field and laboratory applications, delivered by an advanced Concrete Testing Equipment Manufacturer.

- Conforming to IS 2720 standards, this apparatus reflects the quality and accuracy expected from a global Concrete Testing Equipment Manufacturer.

Technical Specifications of Core Cutter with Dolly

- Material – Made from premium mild steel or stainless steel for strength and longevity, crafted by a professional Concrete Testing Equipment Manufacturer.

- Core Cutter Size – Standard 100mm diameter × 130mm height, customizable by the Concrete Testing Equipment Manufacturer as per project needs.

- Dolly Material – Fabricated from aluminum or mild steel with a flat top for uniform force distribution, designed by a reliable Concrete Testing Equipment Manufacturer.

- Handle – Sturdy, detachable handle for smooth field operation, engineered by a trusted Concrete Testing Equipment Manufacturer.

- Hammer Weight – Standard 2.5 kg hammer provided for compact operation, supplied by a leading Concrete Testing Equipment Manufacturer.

- Application – Used to measure in-situ soil density in field and laboratory environments, manufactured by a professional Concrete Testing Equipment Manufacturer.

- Compliance – Fully complies with IS 2720 soil testing standards, ensured by a global Concrete Testing Equipment Manufacturer.

- Weight – Approximately 3–5 kg for the complete set, depending on configuration, crafted by a dependable Concrete Testing Equipment Manufacturer.

- Accessories – Supplied with dolly, rammer, and other essential parts, packaged by an experienced Concrete Testing Equipment Manufacturer.

- Finish – Powder-coated or polished for smoothness and rust resistance, perfected by a premium Concrete Testing Equipment Manufacturer.

- Environment – Suitable for both laboratory and field-testing applications, distributed by a trusted Concrete Testing Equipment Manufacturer.

Applications of Core Cutter with Dolly

- Soil Density Measurement – Accurately determines in-situ density of soil for compaction studies, supplied by a leading Concrete Testing Equipment Manufacturer.

- Field Testing – Widely used in construction sites to check soil density before laying foundations or pavements, provided by an advanced Concrete Testing Equipment Manufacturer.

- Laboratory Testing – Suitable for controlled testing environments in soil mechanics labs, manufactured by a reputed Concrete Testing Equipment Manufacturer.

- Geotechnical Investigations – Essential for projects requiring soil compaction and strength validation, crafted by a trusted Concrete Testing Equipment Manufacturer.

- Infrastructure Projects – Extensively used in road, dam, and building foundation works, offered by a professional Concrete Testing Equipment Manufacturer.

Why Choose Engineering Solutions Equipment as a Concrete Testing Equipment Manufacturer

- ESE is a reputed Concrete Testing Equipment Manufacturer known for high-precision soil and concrete testing instruments.

- With years of expertise, ESE designs durable and standard-compliant tools as a trusted Concrete Testing Equipment Manufacturer.

- Recognized as a reliable Concrete Testing Equipment Manufacturer, ESE ensures each apparatus is tested for accuracy and performance.

- As an innovative Concrete Testing Equipment Manufacturer, ESE provides both standard and customized solutions for soil testing.

- Backed by global recognition, ESE continues to deliver excellence as a professional Concrete Testing Equipment Manufacturer for civil, geotechnical, and research applications.